|

|

|

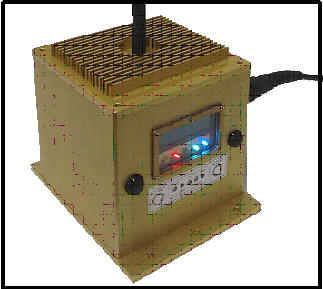

NIKSAR DEVELOPS COMPACT & ROBUST

INSTRUMENTATION UNIT (for remote applications) |

|

Niksar has developed a conditioning monitoring system that

incorporates :

| a single board processor with an 800MHz CPU |

| a data acquisition functionality with analogue and digital inputs and

outputs |

| uses an embedded Windows® operating system |

| instrumentation and data capture functionality and analysis written in

National Instruments LabVIEW® |

| I/O protection and isolation |

| Power requirements : DC power supply input - 16 W nominal for full

speed capture and reporting and a reduced power mode (less than 1 W

average) for remote installations |

| an IEEE 802.11 WiFi connection option for short range networking |

| a GPRS/2.5G connection option for long range M2M connections |

| firmware updating and configuration changes implemented remotely. |

|

|

|

|

NIKSAR DEVELOPS AN ATOMIC CLOCK MONITORING

UNIT FOR NETWORK TIMING INTEGRITY ASSESSMENT |

|

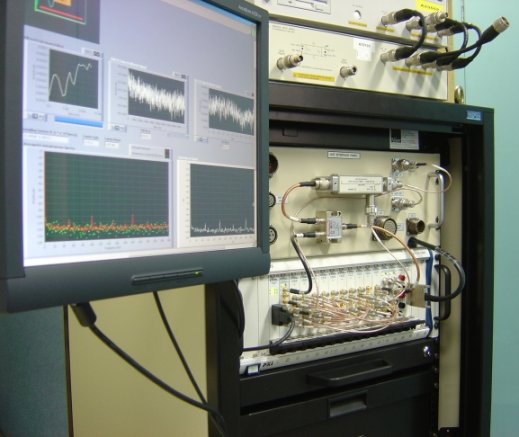

Niksar has engineered and developed a system allowing

network timing reference clocks to be monitored and compared to GPS-derived

timing references. This system has an ability to measure the time drifts of

up to two (Caesium) atomic clocks relative to a high performance GPS-derived

reference. The resolution of the processed timing data is sub-nanosecond.

The timing comparison system uses a National Instruments

2-channel simultaneously sampling high speed digitiser operating at 250

MS/sec (NI PCI 5114 or similar). The application is a dynamically-linked

executable module (.dll) written in LabVIEW® for use with any

calling language.

The reliability of this implementation has been demonstrated

after 18 months in service producing comparative timing data for the primary

reference clocks at several locations in a communication network. |

|

|

|

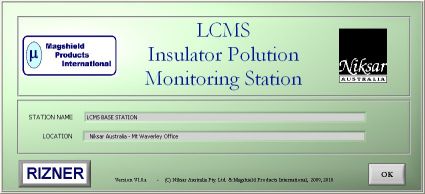

NIKSAR UPGRADES HV INSULATOR

POLLUTION MONITORING SYSTEM |

|

Niksar Australia Pty Ltd in association with

Magshield Products (Aust.) Int. P/L

and RIZNER Pty Ltd has substantially

upgraded and enhanced the insulator pollution and monitoring system which

was previously developed and supplied to the market by Magshield Products

(Aust.) Int. P/L.

The insulator pollution monitoring system is based on the

principle of measuring the leakage current that flows on the

surface of a high voltage insulator with accumulated layer of conductive

pollution.

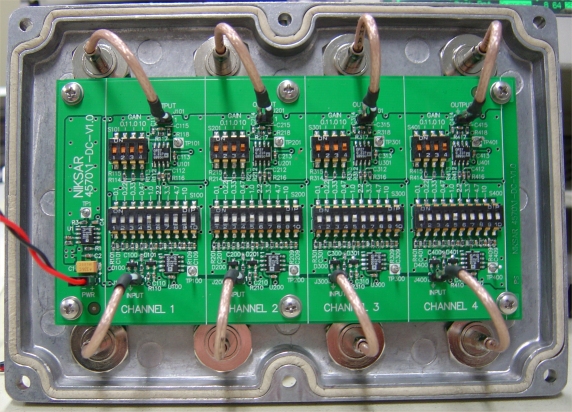

The main features of the upgraded Leakage Current Monitoring System (LCMS) are:

| Wireless and secure communication link between the leakage current

LCMS sensor modules and the base station. |

| Smart LCMS sensor with data processing ability and control functions.

|

| Faster sampling rate. |

| Expanded number of LCMS channels per module. |

The upgraded system relies on wirelessly connected multiple insulator

pollution monitoring modules - LCMS modules, weather data logging, and remote

actuation of insulator wetting module.

Robust surge and transient

protection is a feature of the remote monitoring units and strong encryption

is a feature of the wireless data transmission and control channels.

All data is processed and analysed at the remote collection

points - LC sensors and summary data passed to the base station using WiFi

(IEEE 802.11b/g standard wireless) technology.

|

|

|

|

LCMS Remote Module |

|

|

|

|

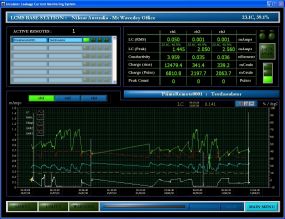

BASE STATION SCREEN VIEWS |

|

|

|

NIKSAR UPGRADES AUTOMATIC TRAIN PROTECTION

(ATP) ANTENNA |

|

Westinghouse Rail Systems Australia (WRSA) has contracted Niksar to engineer

and implement a significant upgrade to the existing ATP antenna to provide

higher levels of functionality, reliability and maintainability.

The new

antenna fits on the undercarriage of a locomotive, and employs OEM RFID

technology to detect and read rail line embedded passive tags as the

locomotive passes over them at any speed up to 160 km/h. A host control and

monitoring system can connect directly through an RS422 serial interface,

eliminating the need for RF connections and feeds.

The

antenna housing is IP67 rated and qualified against railways physical and

electromagnetic environment Standards, and provides a self-contained unit

that is robust and reliable requiring minimal maintenance in service.

|

|

|

The

design and integration engineering involved many activities including:

| design and production of an electronic interface module that provides

high levels of isolation from external electrical and electromagnetic

influences. |

| test engineering for full qualification testing to railways environmental specifications

(physical environment and electromagnetic) |

| production of pre-production prototype units for field testing as a part

of the WRSA Westect II ATP system |

| conversion of the chassis structure from a casting to an NC machined product |

| the redevelopment of the assembly, alignment and test procedures |

| the development of automated production acceptance test facilities |

|

|

The first

batch of these items is to be installed this year under locomotives for

testing in the tropical north of Australia with production for fleet

installation to follow.

The

new TRM provides a self-contained unit that is robust and reliable that

requires minimal maintenance in service. It is mounted under various

locomotives to collect data from track-mounted RFID tags at any speed up to

160 km/h.

|

|

|

|

|

Niksar's Engine Harness Tester Solution |

|

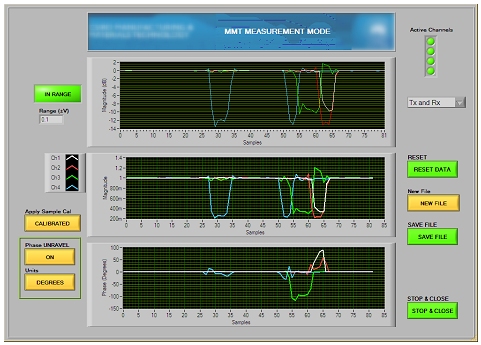

Microwave

Materials Tester |

|

|

JORN

Amplifier

Test Sets

|

|

High Bandwidth Charge Amplifier |

|

Low Capacitance, 20 MHz Bandwidth Charge

Amplifier |

|

SYSTEM DESIGN AND INTEGRATION

SYSTEM DESIGN AND INTEGRATION